Travelling Polymer Screens are engineered for fish protection and the removal of debris from waterways.

AWMA's Travelling Polymer Screen is a debris removal system, typically installed and operated within a channel structure. The automated self-cleaning function is facilitated by scraper or water sprays to maintain a clean and efficient screen surface and water way. The proven polymer material reduces harm to aquatic life, is a long-lasting, low cost, maintenance-free solution that is easy to install and operate for efficient and cost-effective 24/7 debris removal.

AWMA specialise in supplying high quality, high performance screening solutions.

AWMA’s aluminium and stainless steel control products are supplied as standard designs or tailor made to meet specific site requirements.

Features

- Custom designed to meet required size

- Chainless screen design

- Cleaned via scraper or water sprays

- No submerged moving parts

- Innovative drive design

- Low maintenance polymer material

- Various aperture sizes available

- Proven technology

- Compliant with AUS/NZ Fish Screening Guidelines

- Sustainable operation under heavy debris, sedimentation and biofouling conditions

Benefits

- Efficient trash removal from waterway

- Stringy debris is less likely to wrap or cling to the polymer screen material

- Protects fish from entrainment and impingement

- Protects pumps from clogging

- Protects downstream filtration and equipment

- Improved water quality

- Engineered polymer does not corrode

- Polymer less likely to experience ice adhesion

Applications

- Irrigation systems

- Urban water intakes

- Debris/weed dense waterways

- Hydro power facilities

- Water extraction facilities

- Cooling water intakes

Manufacture

- Screen design customised to suit the application

- The Polymer screening material is reliable, durable and low maintenance. Frames are typically stainless steel.

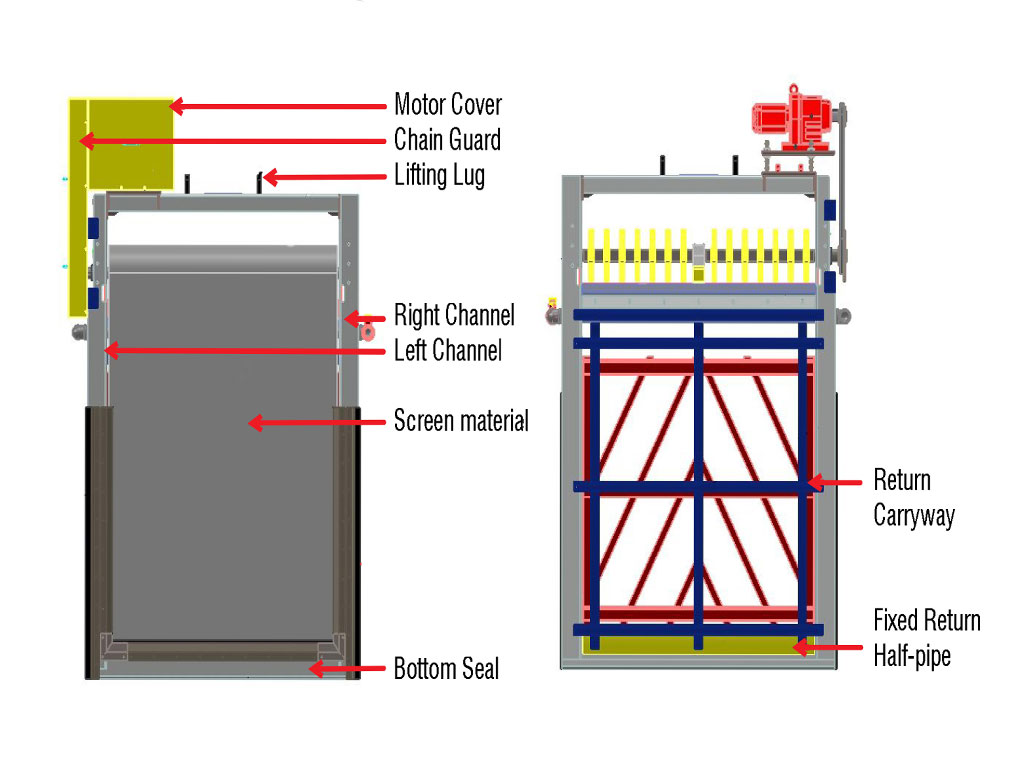

- The engineered polymer modules are interlocked with full length rods. They have no side chains, no submerged moving parts and are designed to remain in the water year round for 24/7 debris removal.

Operation

- The Travelling Polymer debris removal system is typically installed and operated within a channel structure.

- It is powered via an electric motor and gear box, using an innovative drive system.

- A scraper bar facilitates cleaning and debris removal, with an option for water sprays.

Contact AWMA today to discuss our Polymer Travelling Screens or explore our range of other screens and water management systems that we offer.