Single Cylinder Screens and T-Screens provide screening solutions for pumped intakes and gravity offtakes.

AWMA's Cylinder Screens offer an ultimate self-cleaning, water screening solution. This clean and efficient screening solution allows water to flow through the screen into the suction pipe, delivering clean water, without disrupting flow. Screens may be electric, hydraulic or solar powered. The strong, well proven wedge wire screen medium protects fish and aquatic life, whilst delivering high quality water.

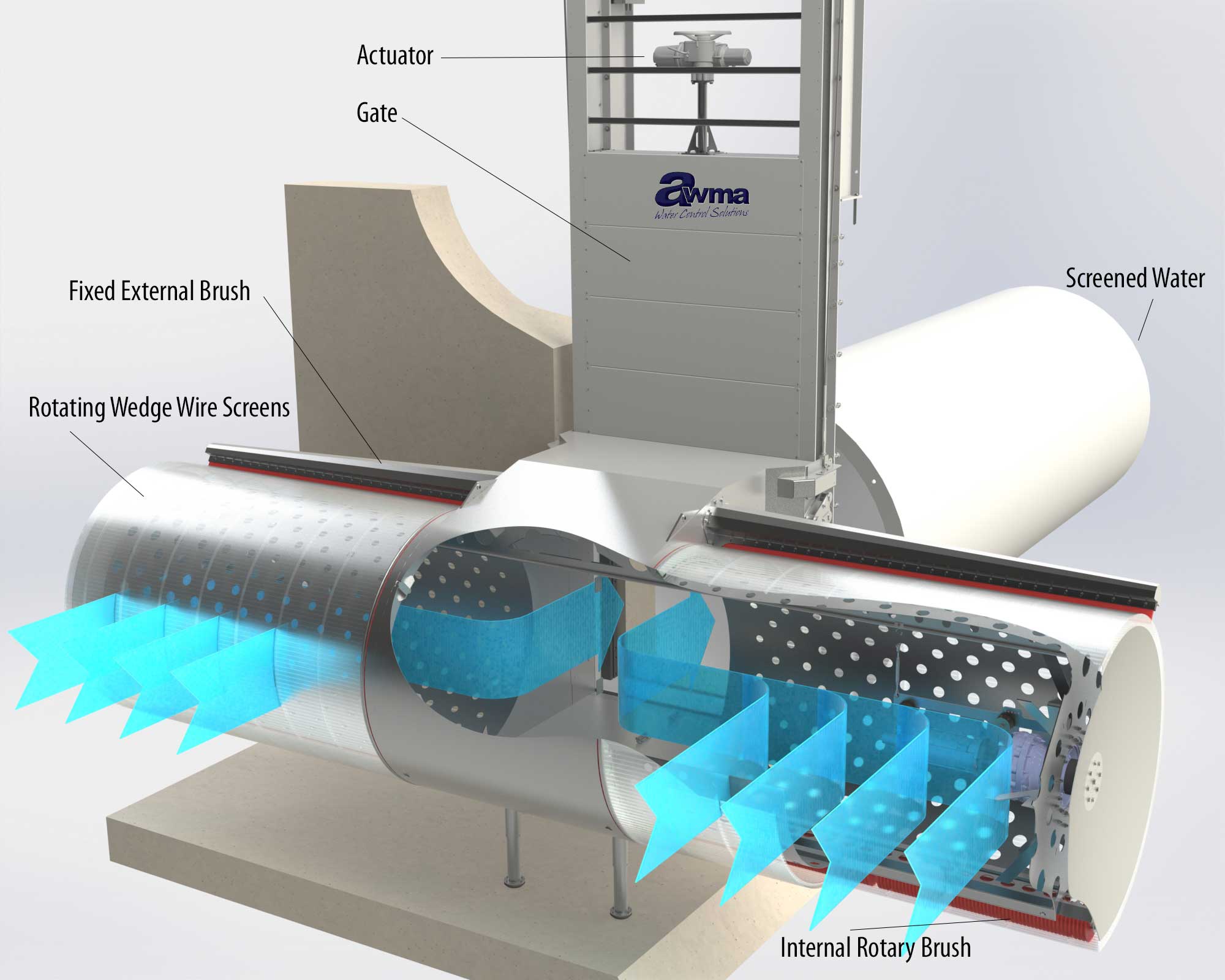

How it works

- Water flows through the wedge wire screen medium (excluding debris and protecting aquatic life),

- The internal drive unit slowly rotates the external wedge wire cylinder,

- Fixed internal and external brush systems clean the screening surface, preventing biofouling,

- The screen drive unit includes electric and hydraulic options which may be mains or solar powered,

- The cylinder screens are programmed by the asset owner to operate as often as required in accordance with predicted debris loads,

- The Single Cylinder Screen allows flows up to 160ML/day (1852 L/s),

- The T-Screen is suitable for flows up to 330ML/day (3819 L/s),

- Configurations for multiple screens, with a large flow capacity are available on request.

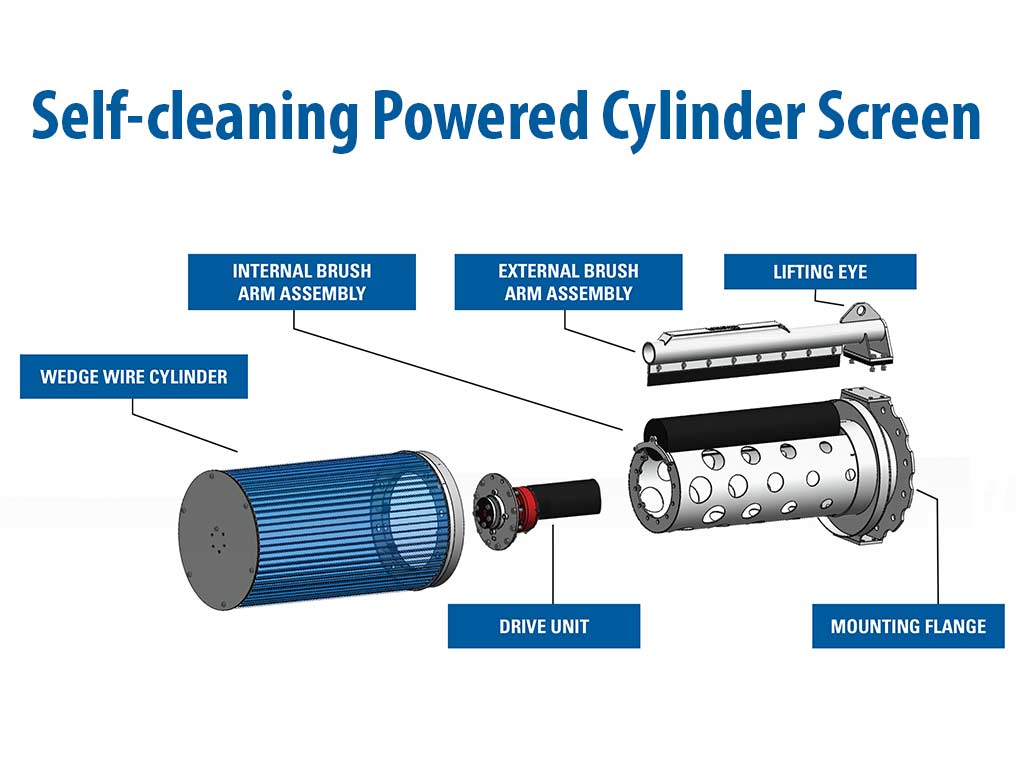

Features

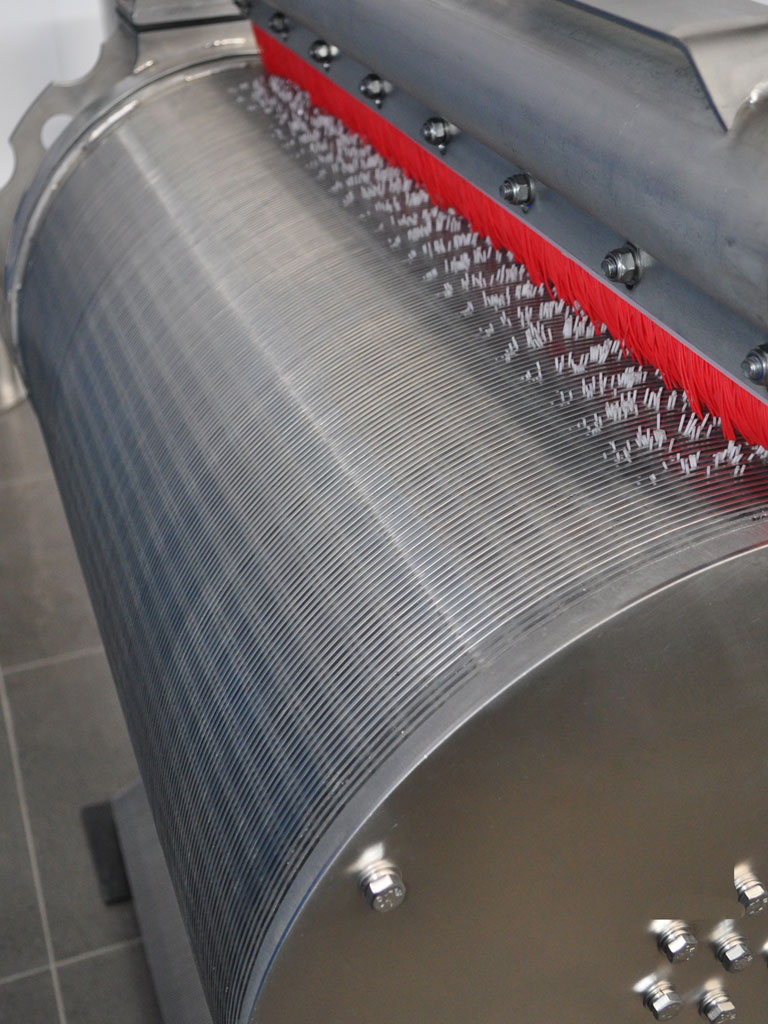

- Various screen aperture sizes available, typically 2mm slot width

- Low maintenance stainless steel construction

- Wedge wire screen medium is strong and durable

- Self-cleaning with internal and external brushes

- Even flow distribution over the entire screen surface

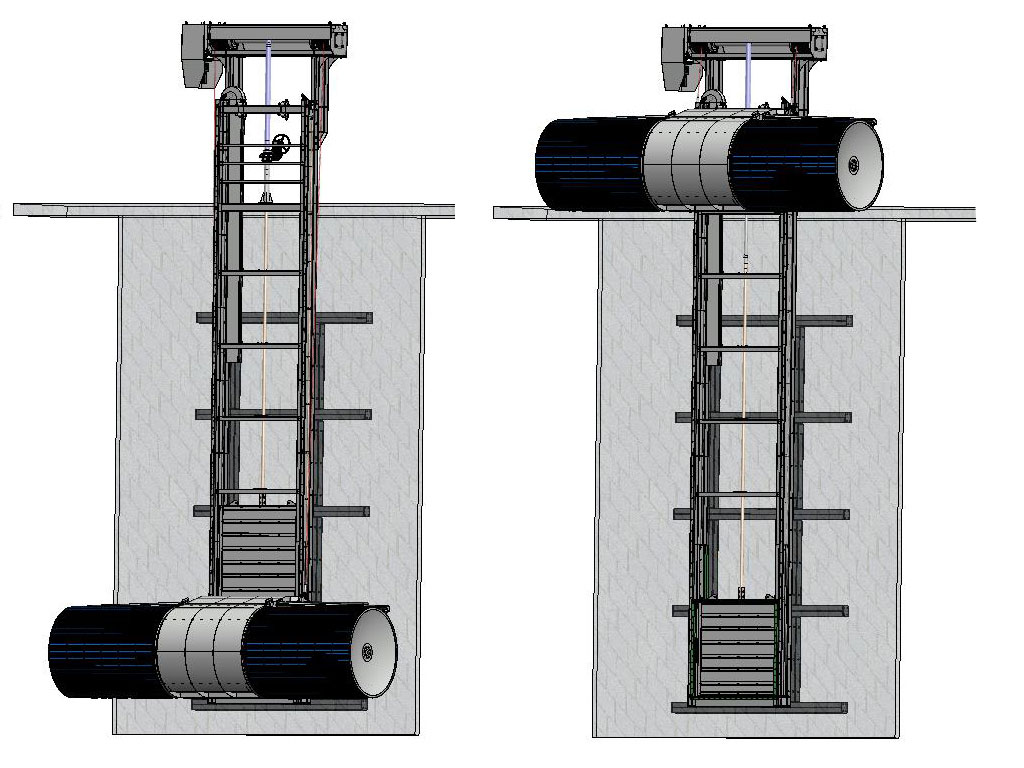

- Options for retrievable or fixed position

- Cathodic protection to minimise corrosion

- Proven technology

- Compliant with AUS/NZ Fish Screening Guidelines

- Sustainable operation under heavy debris, sedimentation and biofouling conditions

Benefits

- Protects fish from entrainment and impingement

- Protects pumps and pipeline infrastructure

- Reduces the loading on, or eliminates downstream fine filtration systems

- Improves water quality

Applications

- Irrigation

- Power plant intakes

- Water extraction facilities

- Cooling water intakes

- Dam inlet towers

- Seawater intakes

Manufacture

- A range of sizes and configurations are available to suit site and application requirements.

- Whilst the screens are self-cleaning and require minimal maintenance, a number of options are available to retrieve the screen to the surface.

Operation

- The screen's self-cleaning drive system may be mains or solar powered

- The Drive Systems may be Electric or Hydraulic

- The self-cleaning screen ensures efficient operation, with fish protection, without comprising flow.

Early project involvement ensures development of the most appropriate mounting and retrieval options, eliminating the need for operators to work in, on or over water. Whilst the screens are self-cleaning and require minimum maintenance, a number of solutions are available for ease of screen retrieval to the surface, which may include a rail system.

Brush-cleaned cylinder and cone screens are designed and manufactured by AWMA under a licensing agreement with Intake Screens, Inc.

Contact AWMA today to discuss screening solutions or explore a range of other water management systems that we offer.