SELF-CLEANING INTAKE SCREENS FOR PUMP INTAKES, GRAVITY OFFTAKES, FISH DIVERSIONS

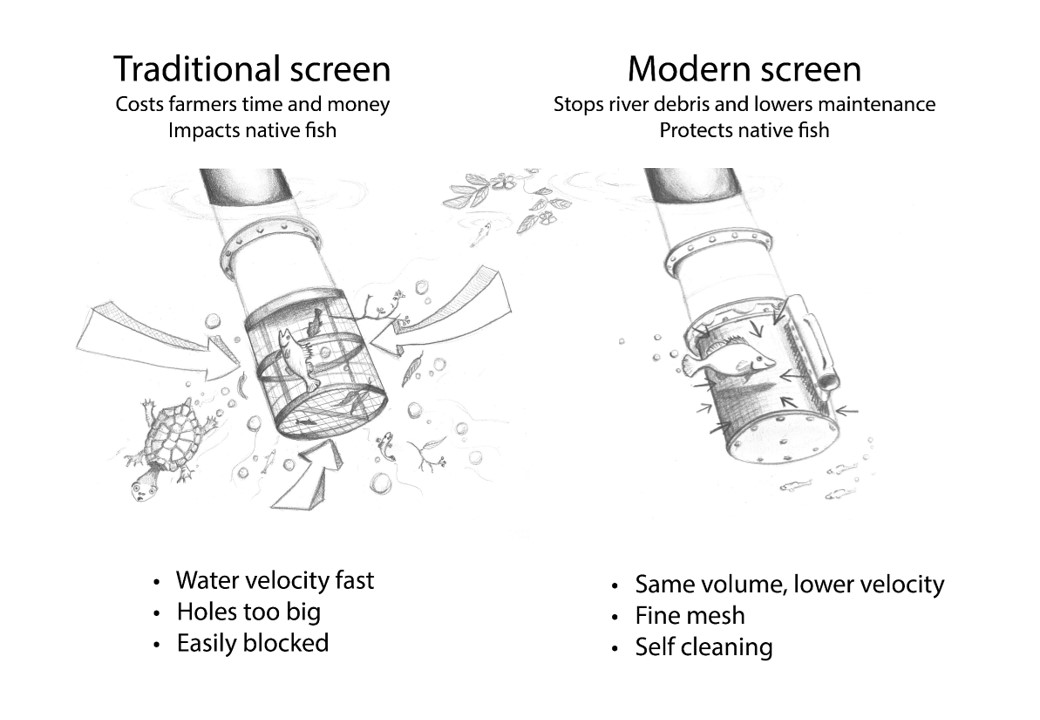

A Fish Exclusion Screen is basically a large filter (like a sieve). The filter has slot sizes from 1mm to 3mm that prevents all stages of fish life from entering through the screen.

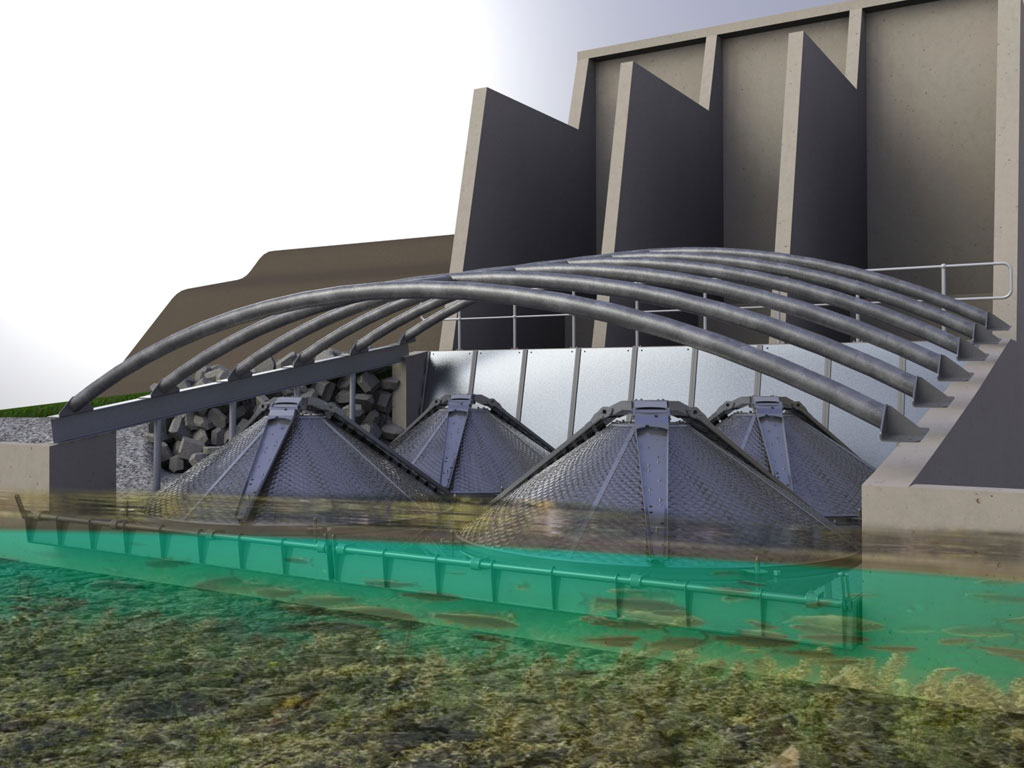

A Fish Exclusion Screen distributes and reduces the velocity of water flow as it is delivered through gravity diversions (channels) or pumped diversions. This often reduces flows from a few metres per second down to 0.1m per second. Subsequently, the diverted flow has a significantly reduced impact on the natural waterway. This is important when protecting floating eggs, juveniles and small bodied fish that can not swim away from high velocities, often becoming entrained in a diversion flow or impinged on a screen.

As expected, if the screens exclude fish and fish eggs they will also exclude other objects in the waterway from entering the diverted flow, subsequently protecting turtles, platypus and other animals as well as isolating weed and debris. This level of debris exclusion reduces system downtime, increasing energy efficiencies and improving water quality. Surprisingly, the Fish Exclusion Screens are basically maintenance free. This is due to the unique self-cleaning features and the distributed screen area ensuring very low approach and through slot velocities.

There are proven designs of Fish Exclusion Screens that have operated in very harsh conditions for up to 20 years with minimal maintenance. Fish Screens are new to Australia but have been used and proven in other countries.

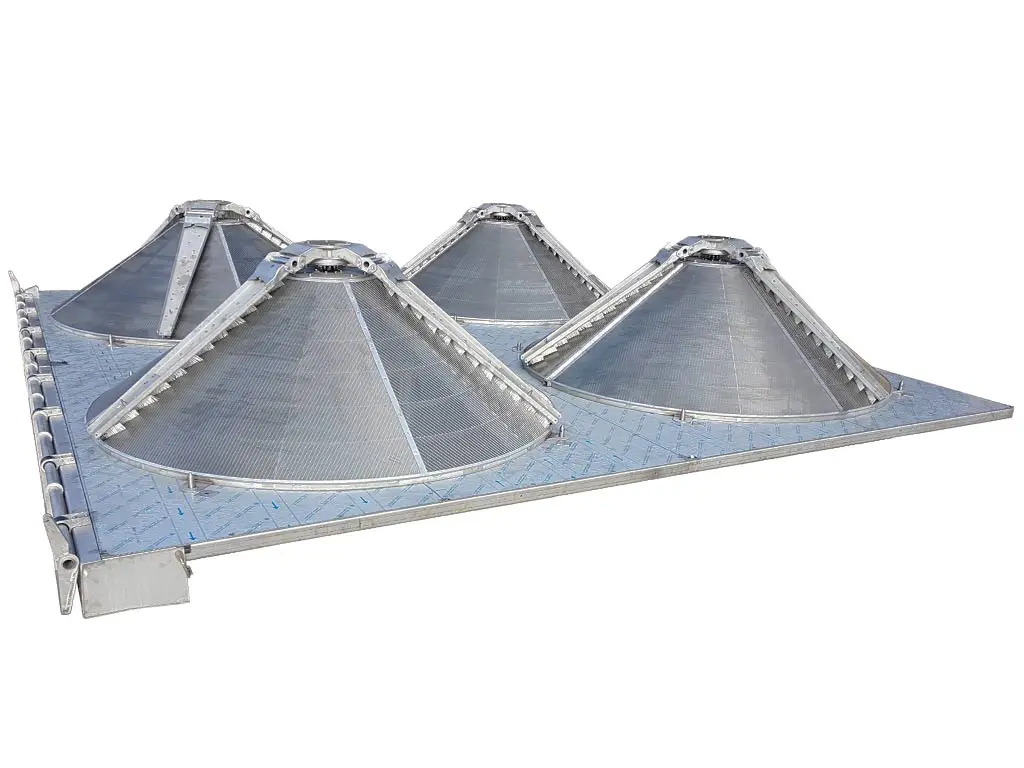

AWMA have developed innovative, field proven Fish Exclusion Screen designs for fish protection and/or debris control. International screen designs have been adapted to meet Australian conditions and performance criteria to protect the interests of both, native fish and irrigator. Solutions are designed for each application to ensure the product meets site specific performance requirements, accommodates local conditions and considers installation criteria to ensure the most effective and economical solution is provided.

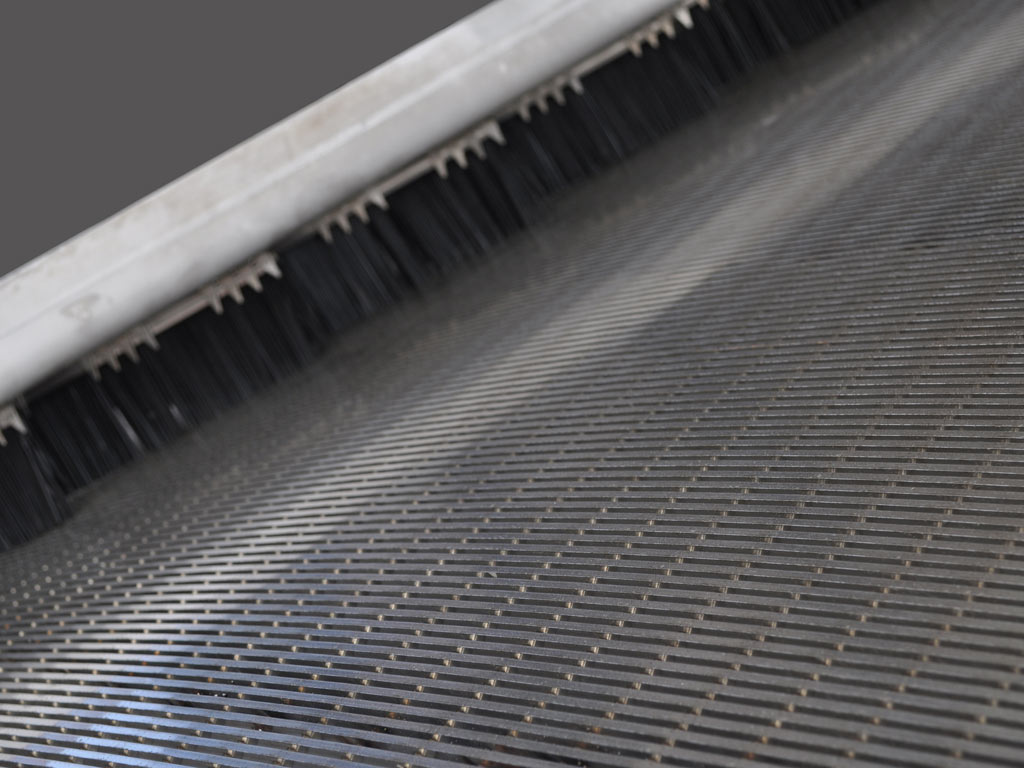

AWMA's unique self-cleaning intake screens provide fine filtration with low approach velocity and even flow distribution, to ensure minimal impingement and entrapment of particles onto the screen. This promotes clean screens, uninterrupted flow, and the protection of aquatic flora and fauna.

FEATURES

- Internal and external cleaning brushes

- Manufactured to suit all pump and gravity offtake capacities

- Suitable for sensitive, abrasive and/or corrosive environments

- Various size screen slots depending on the application

- Durable, robust construction methods and materials

- Customisable to meet site and operational requirements

- Automation options

- Achieving a through screen slot velocity of 0.15m/s or less

- International design with 20+ years’ proven performance

- Programmable screen cleaning intervals ensuring uninterrupted flows

BENEFITS

- Innovative cleaning system increases efficiencies

- lowers maintenance and improves water quality

- Compliance with 'best practice' standards for native fish protection as well as other aquatic life

- Low operation and maintenance costs

- stainless steel materials for long product life

- Excludes debris as well as aquatic flora and fauna

- Improved water quality results in reduced filtration maintenance

- Lower pumping costs from increased pump efficiencies

- Decrease pump system maintenance

- Custom designed to best meet client screening and operational requirements

- Install on new or retrofit to existing infrastructure

- Local customer service and support

- Designed to deliver required flow rates

- Maintaining a clean screen surface

- Customised retrieval systems reduce the need to put divers in the water

APPLICABLE FOR

- Irrigation diversions

- Urban water intakes

- Hydro power facilities

- Debris dense waterways

- Water extraction facilities

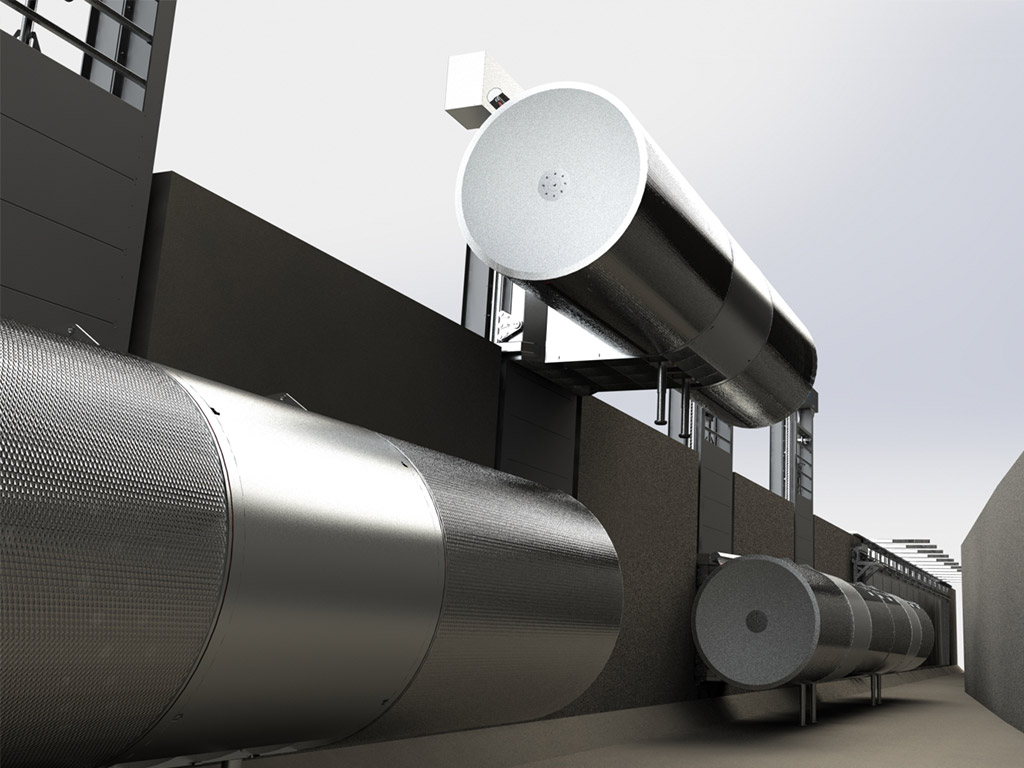

- Cooling water intakes

APPLICATION CONSIDERATIONS

- Minimum and maximum depths

- Size of screened offtake

- Flows (e.g.: Fast, slow, gravity)

- Access (e.g.: Transportation, cranage etc)

- Maintain water distribution

- Access to power

- Cultural, historical and environmental impacts

Brush-cleaned cylinder and cone screens are designed and manufactured by AWMA Water Control Solutions under a licensing agreement with Intake Screens, Inc.

Overcome screening challenges with AWMA’s locally manufactured, supported and serviced range of proven fish exclusion and debris screens.

Blog

Fish Exclusion Screens Presented at IrrigationNZ

AWMA’s Vern Costelow attended the IrrigationNZ Conference and Exhibition as a guest speaker for Infrastructure Modernisation, leading a discussion session on Fish Exclusion Screens. Discussions include: Fish protection or Fish exclusion as an important aspect of fishery management at water diversions. New Zealand concerns about the effectiveness of many traditional fish exclusion technologies. AWMA’s capacity…

Fish Exclusion Screens

AWMA now offer a range of fish exclusion screens to suit various (gravity and pumped) diversion applications including pump stations, irrigation diversions, water treatment plant diversions, hydro power facilities and cooling water intakes. AWMA locally manufacture, support and service a range of fish and debris exclusion screens with a degree of customisation available. The screens…

Best practice management for fishways

World Fish Migration Foundation will be launching three documents to support best practice management for fishways and other fish passage works in Victoria as part of #worldfishmigrationday 21st April 2018.

Water Control News Edition 38 Out Now

See the latest Flood Protection, Penstock Solutions and Modernisation Programs in AWMA’s newsletter: AWMA Water Control News Edition 38.

- « Previous

- 1

- …

- 5

- 6

- 7