SELF-CLEANING INTAKE SCREENS FOR INDUSTRIAL APPLICATIONS

An intake screen is generally used for the extraction and filtration of raw water from rivers, lakes, streams and reservoirs for the purpose of providing for process water, cooling water and other critical water applications.

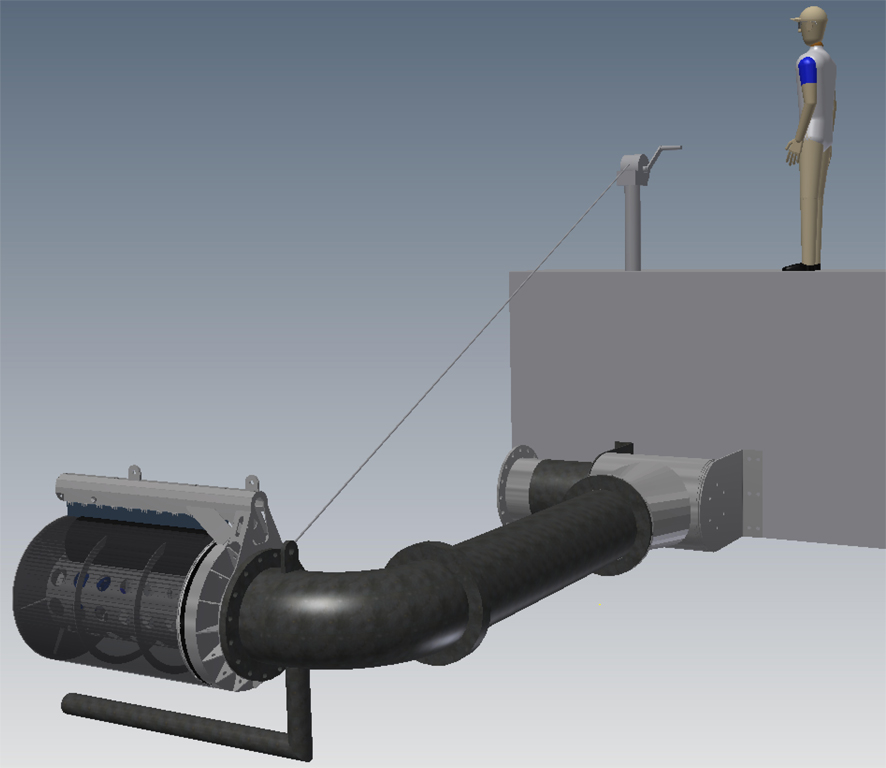

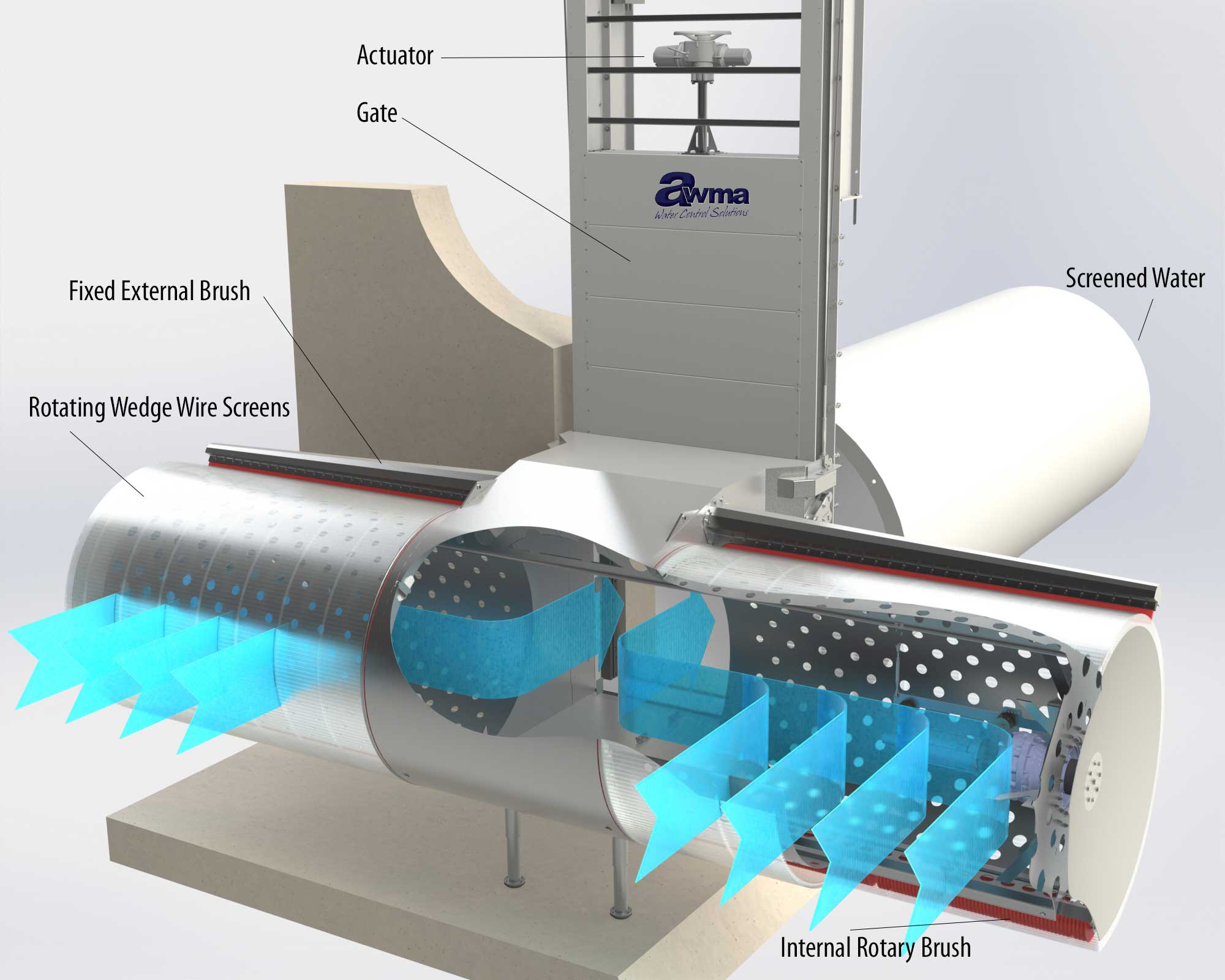

Also known as a raw water intake, inlet screen, drum screen, pre-filter, pump screen or coarse screen, they may take the form of either a cylindrical drum or flat profile design using a very low slot-through velocity to eliminate any impingement of debris onto the screen surface.

The AWMA Self-cleaning Intake Screen solution is custom designed to protect critical and high value assets from costly blockages and damage due to unwanted debris matter. Whether it’s for a power generation, water treatment, desalination, hydrocarbon processing, irrigation, or other industrial application, the AWMA self-cleaning intake screen system is well suited.

The screen material and design dictates very low maintenance requirements. Manufactured from corrosion resistant stainless steel wedge wire, the screen is extremely strong and durable.

Its self-cleaning functionality utilises a rotating screen cylinder (powered or self-propelled) with internal and external brushes to eliminate any debris loading or suspended solid build-up without the need for additional air or water auxiliary cleaning equipment. This intake screen solution provides the perfect replacement for an existing static screen that requires excessive cleaning.

Key Features

- Individually designed to handle flow rates from 0.05 m3/s (50 L/s) and above.

- Multiple screens and large T-intake screens are used to accommodate much larger flow rates.

- An internal flow manifold ensuring a uniform collection of flow across the entire screen surface.

- The robust wedge wire provides a low pressure drop, non-plugging and ease of cleaning screen medium.

- Slot sizes ranging from 0.5 mm and above.

- Reinforced screen construction for higher water depths.

- Proven technology.

- Low maintenance stainless steel construction.

- An integrated dual brush mechanical cleaning system.

- Install your intake screen with either a retrievable system, fixed or on a submergible pontoon.

- We cater for both new installations and retrofit projects.

- Solar power option available.

Key Benefits

- Protects pumps from clogging.

- Protects downstream filtration equipment.

- Improves water quality.

- Low maintenance.

- No additional air or water auxiliary cleaning equipment.

- AWMA’s capability to provide an entire screen system solution

Brush-cleaned cylinder and cone screens are designed and manufactured by AWMA Water Control Solutions under a licensing agreement with Intake Screens, Inc.

Contact AWMA today to discuss screening solutions to suit your application.