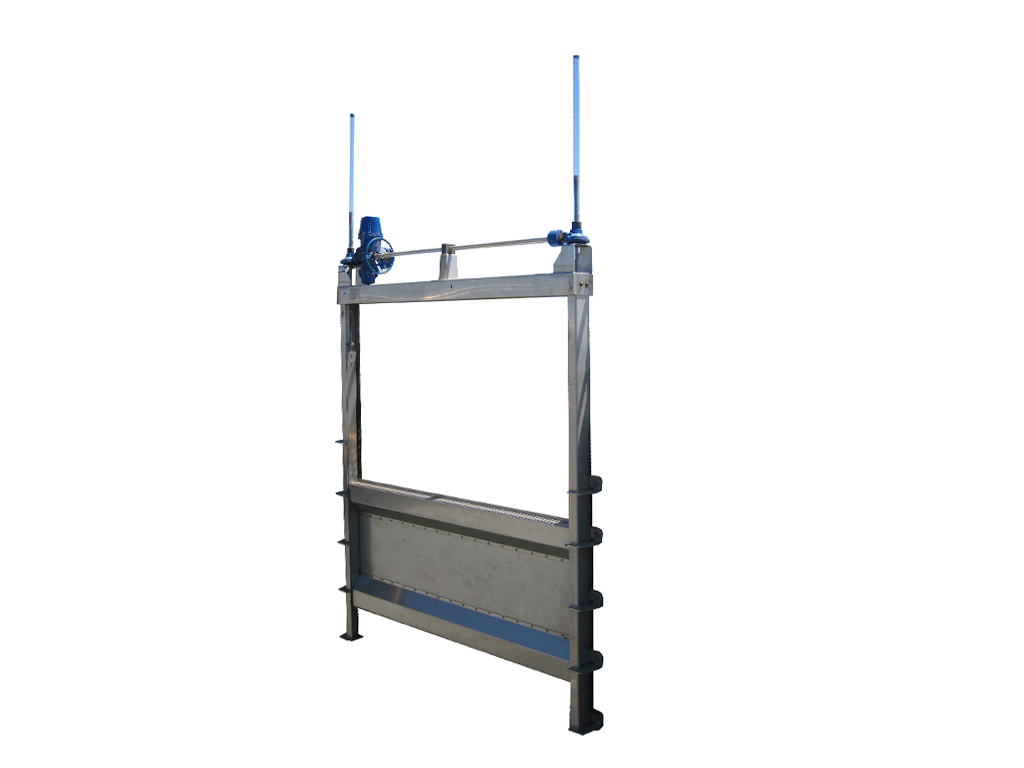

The AWMA DLF Penstock is a downwards opening weir style gate.

AWMA’s DLF Penstock range consists of downwards opening, decant weirs.

FEATURES

• Accurate overshot flow and upstream pool level control.

• The unique design keeps spindles out of the open water way to eliminate obstruction and maintenance issues.

• Bi-directional sealing optional.

• Single and dual spindle configurations available.

• Both rising and non-rising spindle configurations available.

• Custom designed and fabricated to suit any size or shaped orifice.

APPLICATIONS

• The DLF Penstock range is utilised for applications across all industry sectors.

• Isolation and flow regulation.

• Small to medium decanting applications.

DESIGN SUPPORT

• AWMA’s design team will provide full support to ensure the most appropriate solution is developed and specified during the preliminary design.

SIZES

• All AWMA water control gates are custom sized to ensure they meet specific site and operational requirements.

• Customisation reduces installation costs.

MATERIALS

• AWMA select materials to meet a minimum design life of 25 years. Where required, AWMA can offer higher grade materials, coatings and protection systems to extend the design life to 100+ years.

• AWMA use ultra high molecular weight polyethylene (UHMWPE) for penstock door guides and/or wedges to provide maintenance free bearing surfaces.

• Plasticised PVC or EPDM are used for the manufacture of seals. These materials offer superior endurance in wastewater and freshwater applications.

• Materials used for penstock door and frames include marine grade aluminium and grades 304, 316, 2205 and 2507 stainless steel.

• Materials used in the construction of the DLF Penstock range have a high corrosion resistance and can be operated for many years with minimal maintenance.

SEALING

The sealing ability of this gate exceeds that required by the ‘Australian Technical Specification for Fabricated Water Control Infrastructure’.

MAINTENANCE

• The DLF Penstock range has a minimum 25 year design life.

• Minimal maintenance is required offering low ‘whole of life costs’.

• If required, all the wearing components can be changed, with ease, on site.

QUALITY

• All fabrication is in accordance with the ‘Australian Technical Specification for Fabricated Water Control Infrastructure’.

• All stainless steel welding is continuous to avoid crevice corrosion.

• All procedures are in accordance with AWMA’s accredited ISO 9001 Quality Management System to ensure each gate is manufactured to a high standard, tested and ready for trouble free operation post approved installation.

MOUNTING OPTIONS

The DLF Penstocks are typically wall mounted.

ACTUATION SYSTEMS

Choose from:

- Rising Spindle,

- Non-Rising Spindle

- Handwheel, electric, hydraulic or pneumatic actuator.

- Portable actuation systems also available.

OPERATION SYSTEMS

• Integration into new or existing SCADA systems optional.

• Global, web based operating platforms for remote control and monitoring.

DOCUMENTATION AND TRAINING

• Detailed documentation on operation, testing procedures and maintenance will be provided with all AWMA water control solutions.

• Comprehensive on and/or off site training available.

Contact AWMA today for more information on this water gate option or any of our Australian manufactured penstocks or water regulation infrastructure.