Automated Trash Screens remove weed and debris from waterways, often protecting downstream systems and minimising OH&S risks.

AWMA Trash Screen design options are available for bulk and finer filtration requirements.

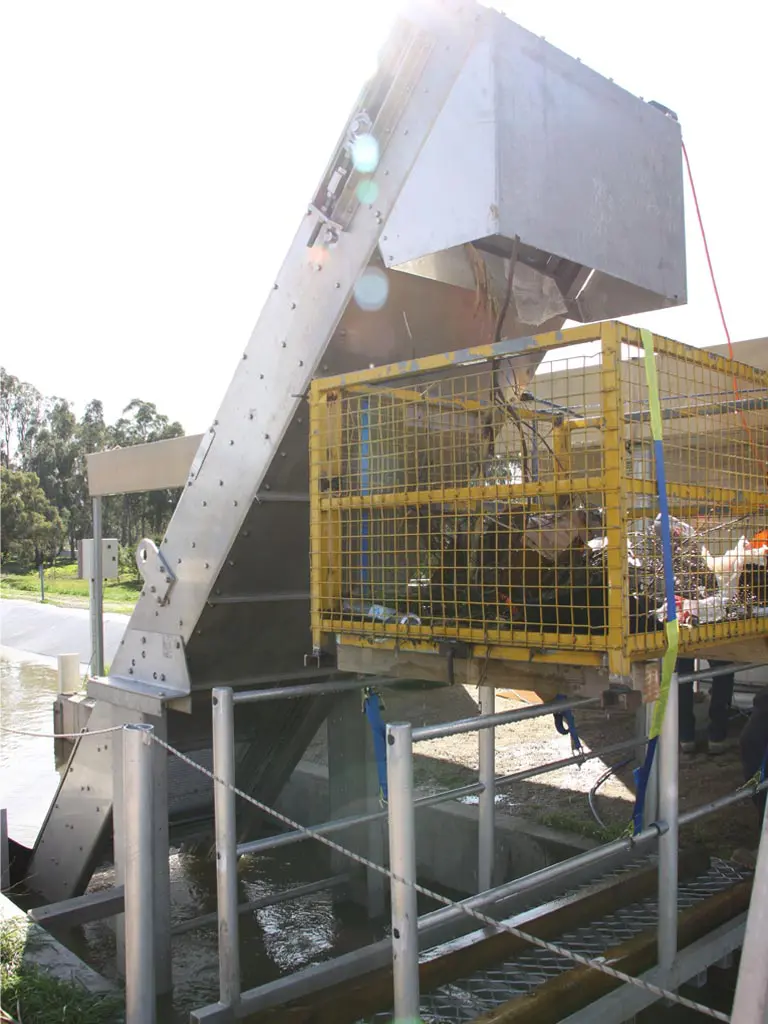

AWMA’s automated trash screens have been engineered to provide an economical, robust and reliable self-cleaning system that can be easily maintained out of the waterway without the need to dewater or bypass the structure.

AWMA’s range of automated trash screens and trash rack cleaning systems are easily configurable to suit different types of debris and structures, with low head loss and they are virtually maintenance free!

Automated Trash Screens are suitable for the exclusion of weed, rubbish, environmental matter and debris. They are designed with safety as the key priority, for the public, wildlife and operators.

Standard or customised, choose from our range of Automated Trash Screen cleaning systems.

Features and Benefits:

- Reliable self-cleaning system.

- Customised bar spacing or wedge wire options to suit debris type and loading.

- Automated trash screens can be either AC or DC powered.

- Low noise level.

- Long life fully sealed polymer bearings.

- Optional spill trays and screen covers.

- Custom designed to suit application size and shape.

- Captures floating and submerged debris within waterways.

- Reduces OH&S risks by eliminating manual cleaning.

- Requires minimal civil works to install.

- Protects downstream infrastructure such as pumps, valves and pipework.

- Designed to require minimal maintenance.

- Improved downstream water quality.

- Designs meet safety regulations on pipes, siphons, pumps and culverts.

- Suitable for exclusion of weed, rubbish, branches and other solids.

Automated Trash Screens are often used in water delivery networks and environmental applications to remove debris from waterways, often protecting downstream systems and minimising OH&S risks.

AWMA offer two main design options;

-

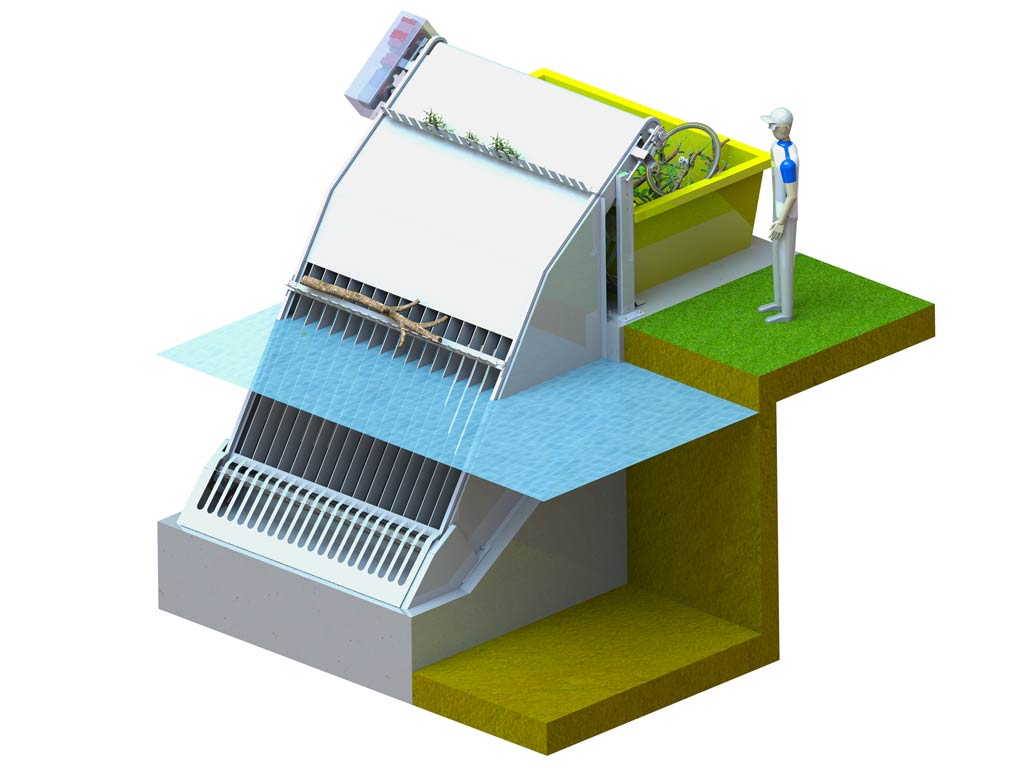

Automated Trash Screen - Coarse Raked Bar Screen

- Designed for the removal of bulk debris such as; weed, branches and general litter.

- Large, robust 'Rakes' capture debris and transport it out of the waterway.

- Typically, vertical bar spacing is between 25mm - 100mm.

-

Automated Trash Screen - Wedge Wire Fine Brushed Screen

-

- Designed for the removal of finer sediments such as weed, general litter, environmental matter and vegetation seeds.

- Features stainless steel wedge wire mesh for finer filtration.

- 5mm aperture wedge wire as standard.

Every product is custom designed to meet site and operational requirements, allowing for choice of material, screening aperture size, structure size and operational systems.

Applications:

The AWMA Trash Screens are utilised for applications including:

- Pipes

- Pump Intakes

- Siphons

- Stormwater Systems

- Floodways

- Channels

- Water Distribution Systems

- Wetlands

- Mining

AWMA’s Automated Trash Screens utilise either raked or brushed elevator's (or flights) attached to a rotating chain system. This is driven by a motor and gearbox coupled to a drive shaft. The result is a reliable, autonomous, self-cleaning system. These debris removal processes can remove bulky objects and/or fine debris from the front of the screen to avoid blockages. Debris is transported upwards, out of the waterway into removable disposal bins, conveying chutes or troughs. Optional water sprays are available.

Automated cleaning of trash screens eliminates risk to operators in performing manual raking processes.

Specialising in high quality, high performance water control infrastructure for all industries, AWMA can supply you with exceptional aluminium and stainless steel flow control products and exclusion screens suited to your specific application.

What are Trash Screens and Trash Racks?

Trash Screens and Trash Racks are designed to capture floating and submerged debris within water way systems. Typically made from stainless steel and are ideally automated to ensure safe removal of weed or debris from the waterway.

AWMA are a leading, Australian, trash screen supplier. You can enjoy complete peace of mind with assured quality across our entire product range.

For an effective and innovative trash rack cleaning system, debris screens or any of our other aluminium or stainless steel flow control products, contact us today!