With an overall width over 7m and weighing over three tonnes, the T-style cylinder screen has nearly 30 square meters of effective screen surface area.

AWMA were engaged by Monadelphous Engineering to supply an Intake Screen within the Waitaki Valley, for Kurow Duntroon Irrigation Company (KDIC) in New Zealand.

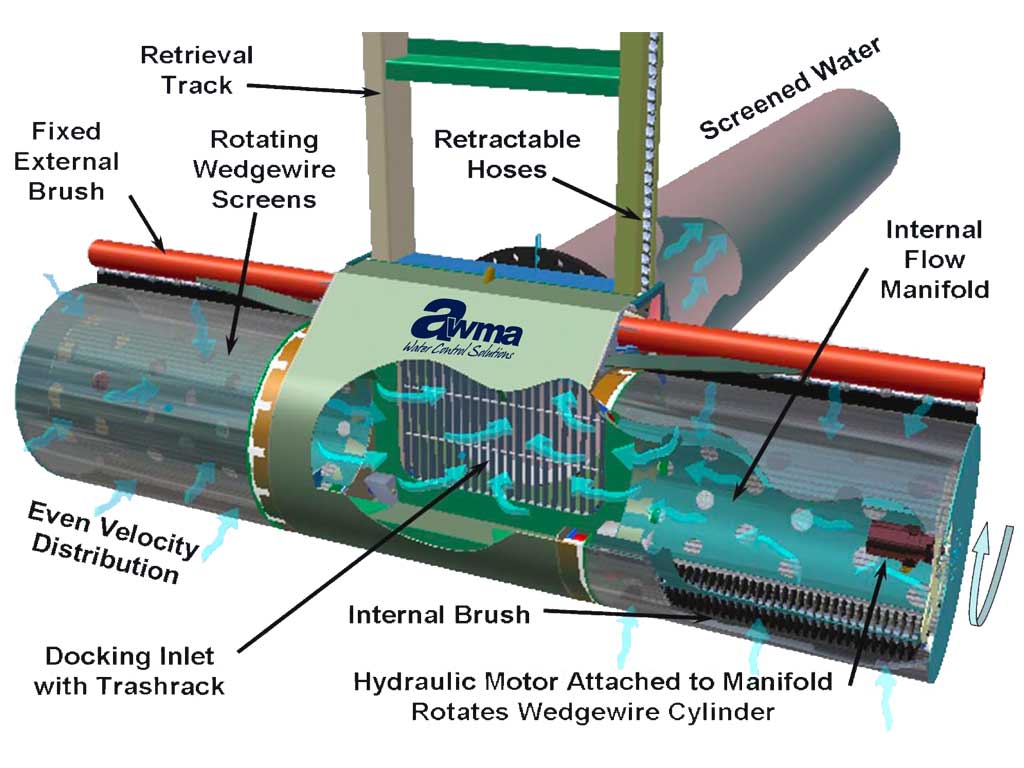

The Self-Cleaning Cylindrical Intake Screen was supplied with a Retrieval System and Isolation Gate.

An innovative self-cleaning mechanism rotates the two external cylinders, using internal and external brushes to ensure the wedge wire screen surface remains clear of debris, algae and weed.

AWMA’s Intake Screens are designed for even, low velocity flow distribution across the entire screen surface which is crucial to meeting fish exclusion criteria (per ‘Fish Screening: good practice guidelines for Canterbury’).

At KDIC, raw water is screened through a 3mm aperture wedge wire medium with an approach velocity less than 0.12m/s (for fish protection) and is then piped into the irrigation scheme.

The Retrieval System is 13.2m high with an integrated track system, isolation gate and headstock that houses an electric gearbox and drive motor. The Retrieval System provides an effective method of raising the intake screens should inspection or maintenance be required. Raising the screens to the surface greatly reduces the risks and costs associated with maintenance, when compared to traditional methods using divers.

Integrated within the retrieval frame is a vertical, manually operated isolation gate with a non-rising spindle, manufactured from grade 316 stainless steel. The purpose of the gate is to eliminate debris entering the pipeline when the screen is raised.

Brush-cleaned cylinder screens are designed and manufactured by AWMA under a licensing agreement with Intake Screens, Inc.