Construction of the new Port Hinchinbrook Sewerage Treatment Plant (STP) in Cardwell, Queensland, is well underway.

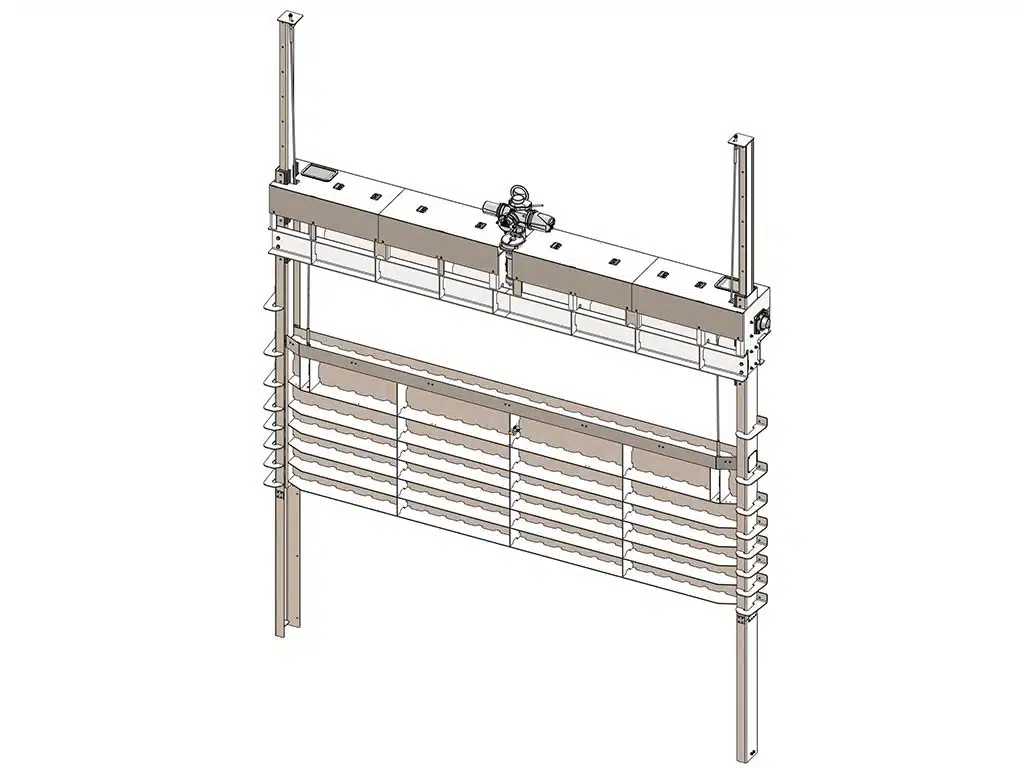

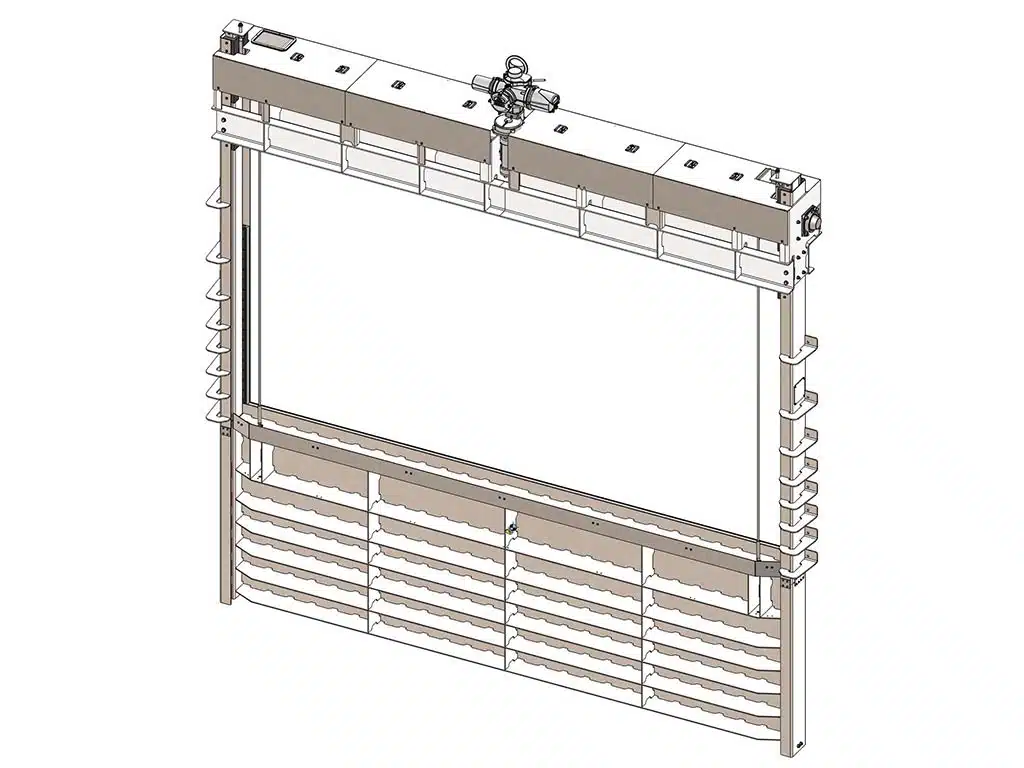

AWMA was engaged by Haslin Constructions to design and manufacture a specialised downward-opening decant gate for the project.

AWMA’s Decant Gates are engineered for high-frequency, high-duty cycle operations in decant applications. A standout feature is the positive cable drive system, which addresses the common wear and tear issues seen in traditional spindle drive systems under heavy use.

This innovation extends the drive system's service life, leading to lower maintenance, reduced whole-of-life costs, and minimal system downtime.

The gate, constructed from grade 316 stainless steel, is 5.5 metres wide and 1.9 metres high, capable of withstanding up to 2.0 metres of off-seating water pressure. It also features an integral scum baffle to prevent surface contaminants from passing over the gate during the decant cycle.

The twin cable drive system is powered by a three-phase 415VAC electric actuator, connected to a multi-turn gearbox.

For more information on this project or to explore AWMA’s gate solutions for urban applications, please contact our gates team.