AWMA manufacture Automated Trash Screens that safely and effectively remove seeds, weed, rubbish and other debris from waterways.

AWMA’s latest Trash Screen design features fine, wedge wire filtration with a brushed self-cleaning mechanism. This provides reliable, OH&S compliant, automated screening to remove bulk and fine debris from waterways. The screening process also protects downstream infrastructure including pumps, pipelines and irrigation spray nozzles. AWMA screens are ideal for applications requiring an economically viable option for automated screens.

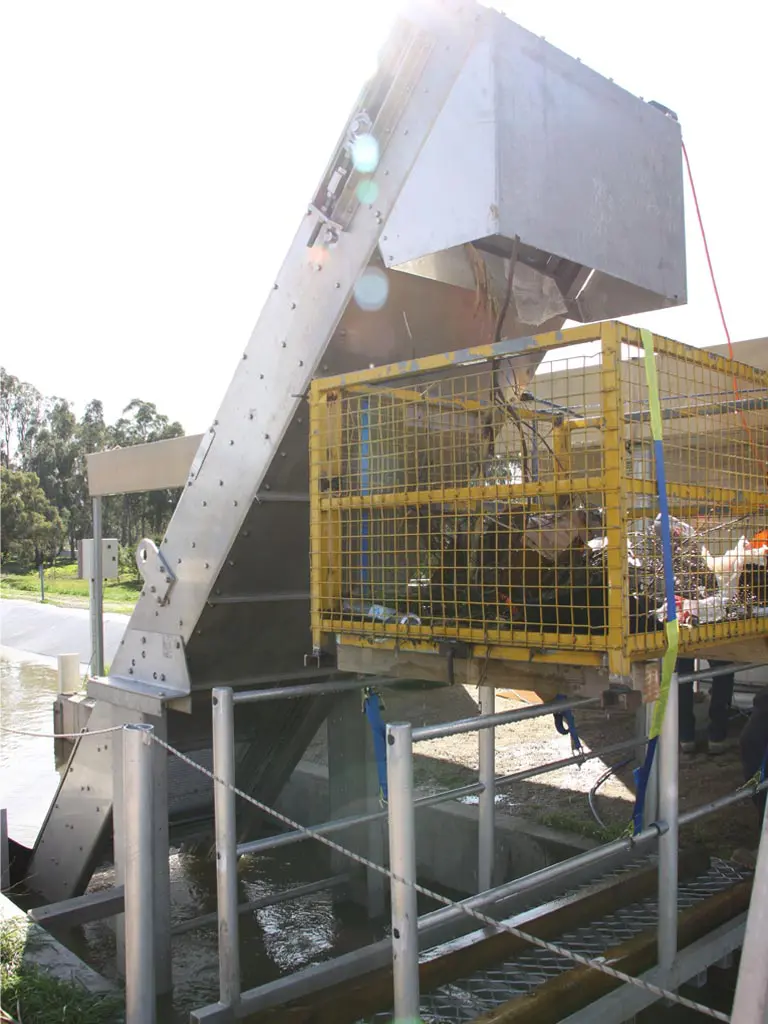

Engaged by the Victorian Government’s Level Crossing Removal Project via its Western Program Alliance, AWMA custom-designed twin Automated Trash Screens for an urban water diversion system in Victoria.

The previous method of manually raking weed and debris was no longer safe or viable.

AWMA screens are engineered to site specific requirements and conditions. For this project that meant designing a Trash Screen that could automatically remove large amounts of weed, seed pods and a variety of rubbish out of the waterway and into disposal bins. It was crucial that the process was automated as the weed present was seasonal with quantities varying from hour to hour, day to day.

A 100% capture rate was also required, to extract weed and urban debris greater than 5mm as seed pods were causing issues for farmers by clogging irrigation spray nozzles, requiring endless maintenance. A low whole-of-life cost was a key design criteria which led AWMA to deliver a product with a 50 year asset life.

To date AWMA Automated Trash Screens have been manufactured up to 3.5m wide, with no restriction on depth. The screen medium is a stainless steel wedge wire with 5mm aperture to capture weed, rubbish and debris.

The benefits of self-cleaning trash screens include:

- reduced operator risk by eliminating manual cleaning requirements

- improved efficiencies from extracting water through a clean screen

- higher water quality

- reduced damage to downstream infrastructure

Design options for AWMA Automated Trash Screens include a raked bar system for larger debris, or a brushed wedge wire design for finer filtration. Both options have a range of aperture sizes available to accommodate site specific debris loads and characteristics.