Melbourne Water has been working in partnership with AWMA on a debris removal project to decrease long term maintenance and operation costs as well as reducing OH&S issues in remote locations.

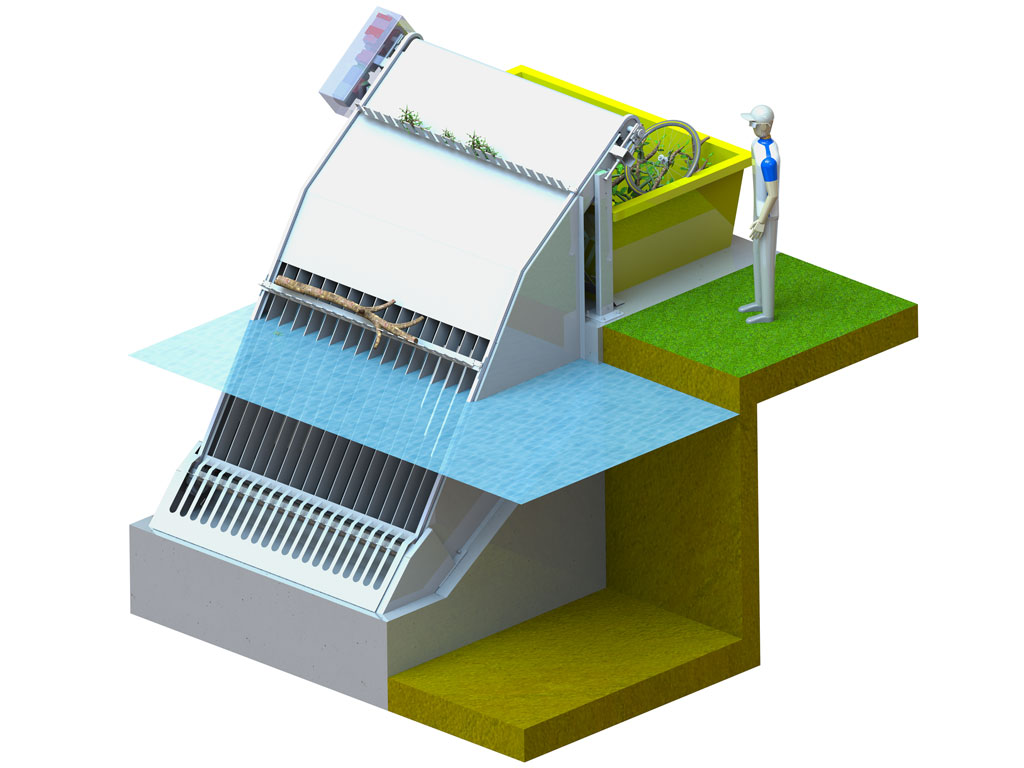

AWMA have custom designed, fabricated and installed an automated trash screen 5m high x 3m wide to be remotely monitored and controlled via Melbourne Water’s SCADA system.

The trash screen is a new approach to debris removal, a way forward to a more sufficient and cost-effective operation system.

The project site features an inlet basin fed by an open channel aqueduct. This site collects a large amount of debris due to the adjacent eucalypt forests. Prior to the automated trash screen, Melbourne Water operators relied heavily on alarms, requiring on-call staff to manually clear away debris, often in adverse conditions.

The trash screens high strength design is virtually maintenance free, manufactured from grade 316 stainless steel and powered by an SEW Eurodrive motor and gearbox.

The AWMA trash screen will reduce OH&S risks and increase operational and resource efficiency.

Trash screen designs are application based and flexible depending on the type of debris to be manually or automatically removed. The investment will provide long-term reduced operational, maintenance and whole of life costs.