AWMA’s powered trash screen was recently re-engineered to provide a more economical, robust and reliable self-cleaning system that can be easily maintained out of the waterway without the need to dewater or bypass the structure.

The latest automated self-cleaning trash screen has been installed for Barwon Water in a remote area of southern Victoria.

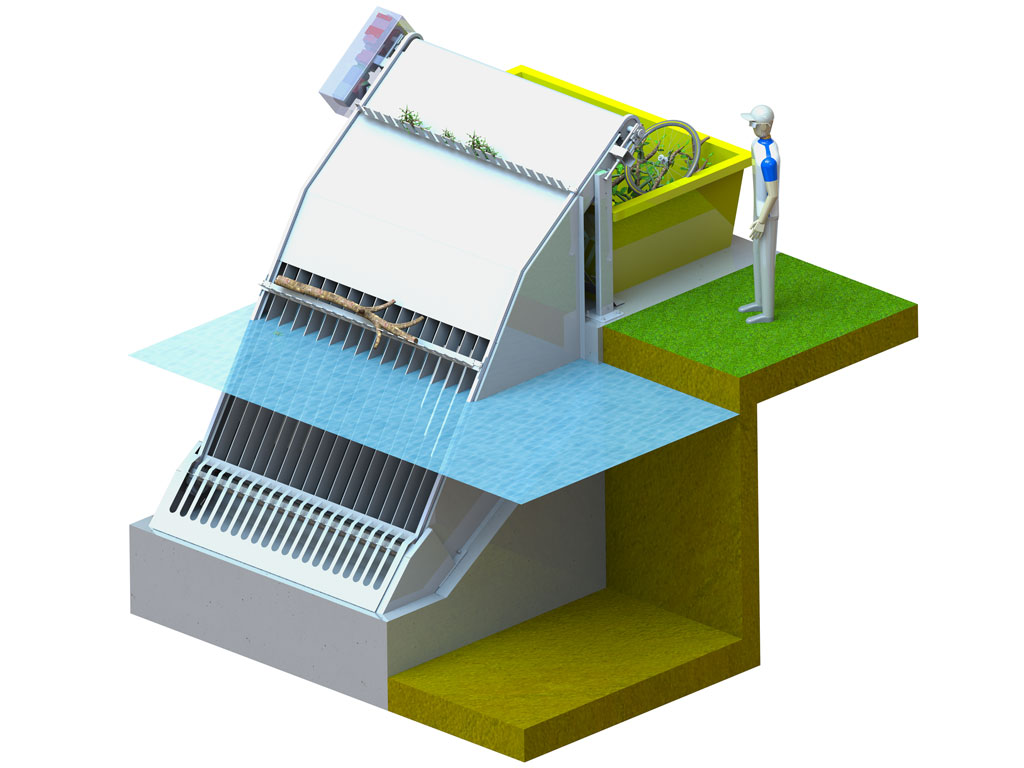

The structure provides over 4.0m² of clear opening area at the entrance to an underground syphon.

Trash screens are often used in water delivery networks and environmental applications to remove bulk debris from waterways, often protecting downstream systems and minimising OH&S risks.

AWMA’s powered trash screens utilise cleaning rakes attached to a rotating chain system which is driven by a motor and gearbox, coupled to a drive shaft. This process removes bulky objects from the front of the screen to avoid blockages. Debris is transported upwards, out of the waterway into removable disposal bins, conveying chutes or troughs.

Automated cleaning of the screen eliminates risk to operators in performing manual raking processes. No additional consumables, such as brushes or service water is required. The chain system may be detached from the frame allowing the cleaning rakes to be removed and reinstalled easily, during full maintenance checks.

AWMA powered trash screens can be configured to suit different types of debris and structures.