The TNIS Pump Station upgrade project was the first install of 7 priority pumping sites, requiring 24 screens, along the Macquarie River, as part of the NSW Government's Regional Recovery Program.

Millions of native fish are being removed from our rivers, creeks and dams every year. There is substantial historical and scientific evidence of these losses. Modern screening has the potential to reduce these losses by 90%. It is the missing piece of the river-restoration puzzle.

The AWMA Fish Screen is a modern, fish and debris exclusion screen solution. The screen will not pass any debris larger than 2 mm through to the pump system and will never be compromised by debris blockages at the pump inlet.

The result is:

- Consistent, optimum pump performance

- Reduced energy consumption; less greenhouse gas emissions

- Reduced wear and tear on the pump

- Less maintenance

- Extended pump life expectancy

- Reduced whole of life costs

- Minimal backwashing required

- Consistent maximized efficiency energy consumption

- Improved pumped water quality

- No loss of native fish or other aquatic animals

TNIS T-Screen Project Details

AWMA custom designed and manufactured a fish and debris exclusion screen for installation on an existing pump station intake.

- To enhance pump performance and efficiency.

- Allow viable water extraction at historically low river levels and historical flow rates.

- Screens were to be high quality, long life, low maintenance, low whole of life cost assets.

- Screens were to have a retrieval system to allow safe and easy access for maintenance and inspection.

- Screens were to meet NSW DPI fish protection guidelines. https://fishscreens.org.au/

- Allow vertical, single, fully assembled removal of pump column for maintenance.

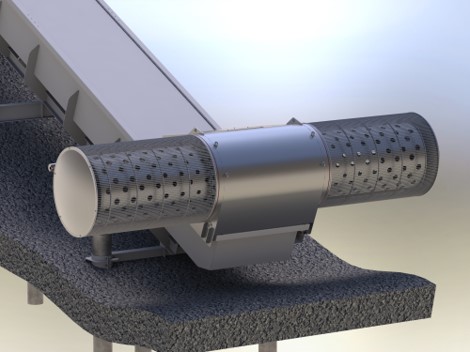

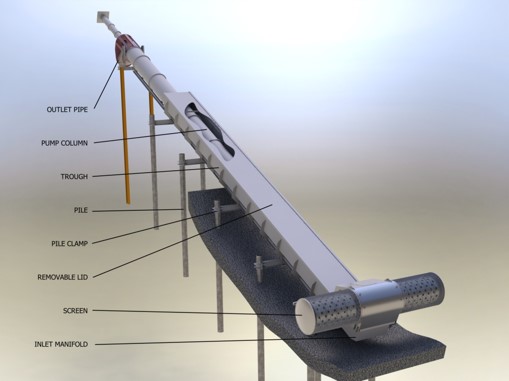

- The screen sits over the pump inlet manifold.

- Typically, the screen is automatically cleaned by two brushes acting on the rotating screen once a day. One CW rotation and one CCW rotation (approx. 2 minutes operation per 24 hours).

- The screens are rotated hydraulically by a centralised automated hydraulic control system located on the riverbank.

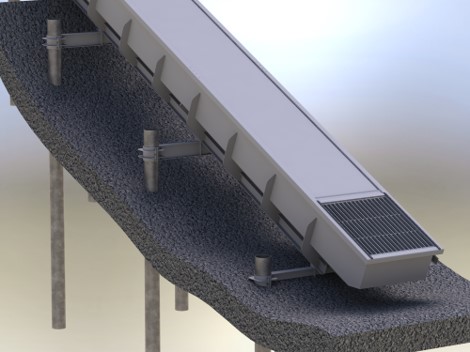

- The screen can be raised and lowered on a rail system via a hydraulic winch.

- The screen will be accessible safely by a new access platform.

AWMA has developed a pump mounting system (trough) that allows removal via vertical lift of the pump without column disassembly.

The manifold and screen design:

- Has been proven using CFD modeling.

- Significantly reduces velocities entering the pump suction reducing the likelihood of vortexing during low river extraction.

- Will never block with debris.

- Significantly reduced back flushing.

- Increases inlet surface area by over 500%, reducing approach velocities from > 3 m/s to less than 0.2 m/s.

- Brush cleaning physically removes and prevents bio-fouling build up on the wedge wire screen surface, both externally and internally.

The addition of the T-screen installation completes early works involving the installation of four Cone Screens.

Together they screen up to 800 million litres of water per day from the Macquarie River, that is delivered to 33 regional farms. The AWMA screening solution eliminates fish and debris entrainment whilst guaranteeing reliable irrigation flows.

Brush-cleaned cylinder screens are designed and manufactured by AWMA under a licensing agreement with Intake Screens, Inc.

We can still obtain the pumping flow rates and volumes we require without any negative impact on the river system or the pumps.

In fact.. our scheme members have noticed cleaner water from the pump station, resulting in better irrigation on-farm due to reduced debris being delivered.

Improved water delivery, combined with native fish protection, is a win-win for our members and the environment. "

- Shane Smith TNIS Manager