Lift shafts are prone to water ingress due to weather events, flash flooding, stormwater issues and extreme flood events. In these situations when water finds its way into a lift shaft the lifts are decommissioned for a prolonged period, often resulting in the relocation of residents and businesses in the affected building until it can be declared operational. Corrective action for a lift well that has been flooded is expensive and time-consuming. Repairs can include cable replacement, structural inspections and mould treatment.

Recent flash flooding events have seen an increase in flood mitigation and asset protection projects for multilevel buildings.

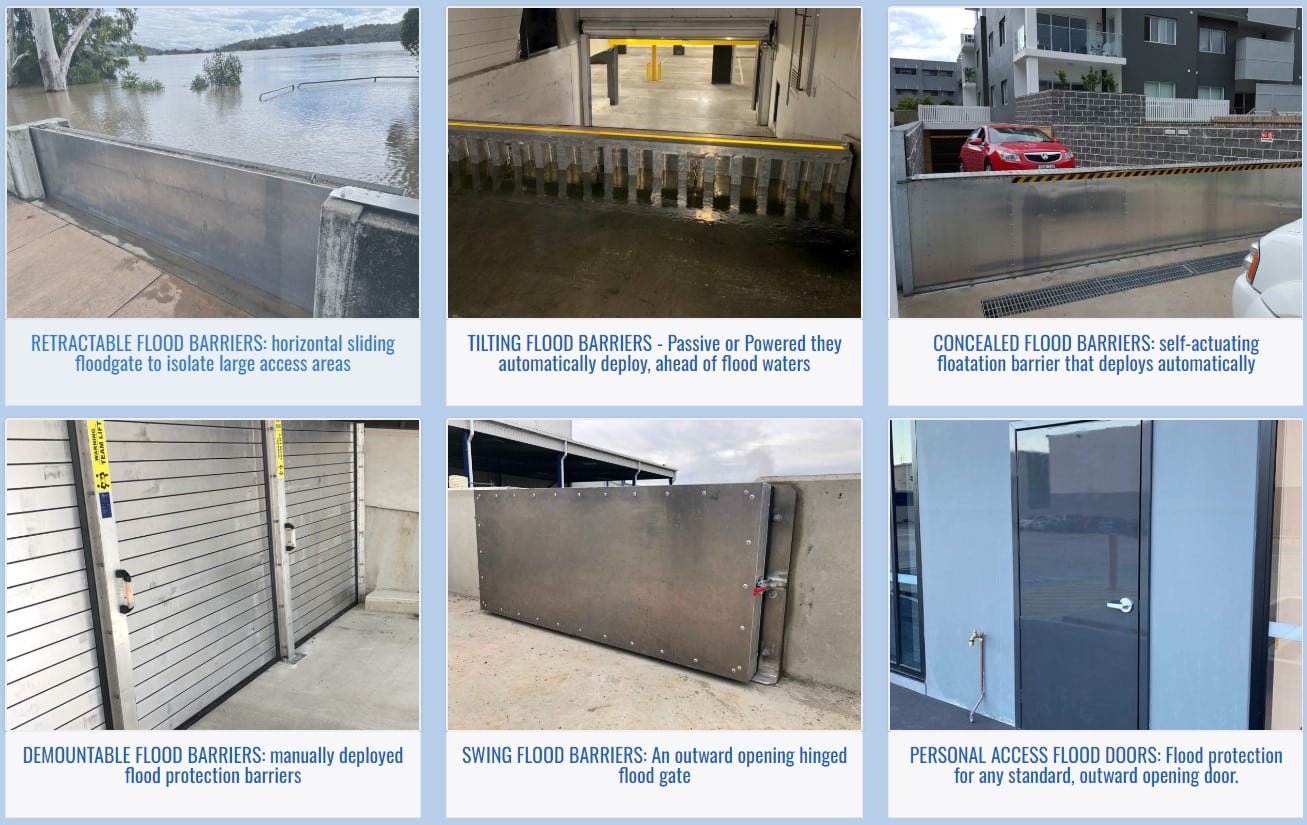

AWMA's FloodFree range has numerous products customised for lift wells and basement doors across commercial, industrial and residential building applications.

FloodFree barriers have been proven to protect lift wells from water ingress. They include options to suit the degree of flood warning, alert times and viable operational systems in an emergency. A range of flood barrier solutions are available for lift well applications such as passenger lifts, freight elevators, residential lifts, commercial elevators,

traction lifts and low pit lifts, they include:

• Demountable Flood Barriers are manually deployed by one or two people, therefore requiring a greater flood warning alert period allowing time to install them. Each barrier segment weighs approximately 4kg per metre. Demountable Flood Barriers are custom-made in a variety of configurations to meet site specifications. Side panel covers, included as standard, are manufactured from a durable brushed stainless steel material, protecting the seals from exposure. A variety of storage and transport solutions are

also available.

• Demountable Bulkhead Flood Barriers provide 100%, full perimeter sealing around lift wells and door frames. Barriers are often stored adjacent to the access point for fast and effective deployment prior to a flood event. They are usually designed as a single-piece barrier. In the installation pictured below, the bulkhead was installed on an overhead linear rail system for ease of installation with no difficult manoeuvring required. To deploy, the barrier is disengaged from the storage rack and slid along the track, the floor sill rebate cover is removed then the barrier is positioned against the opening and bolted into place. Please see our web page for more information.

• Passive Tilting Flood Barriers are ideal for sites with minimal flood warning. They are a self-actuating, or passive, flood barrier. Permanently installed at the access point they self-deploy in response to rising water levels, isolating the protected assets from water intrusion. As water levels recede the flood barrier lowers autonomously. There is no human intervention involved to deploy the barrier. They require a minimal depth to install, sit flush at ground level and can accommodate trafficable loads (from pedestrians to trucks and forklifts). They also have a range of material coatings and side panel options available.