Fulton Hogan engaged AWMA to design, manufacture and supply bulkhead gates, frames and storage racks, for the Luggage Point Outfall Channel remediation project.

As part of Urban Utilities Metro Treatment Plant capital works program, Fulton Hogan was required to complete a sequence of night shift shutdowns with all flow to be isolated to the Luggage Point STP outfall channel.

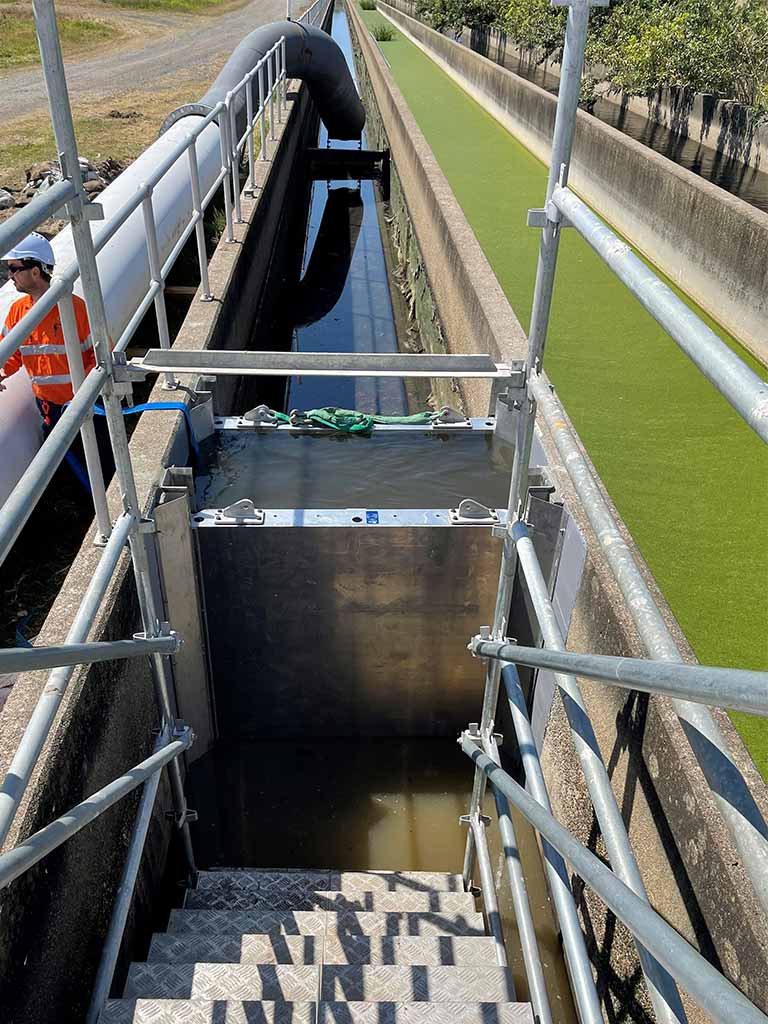

Isolation of the Luggage Point STP required 2 x sliding bulkheads for the main channel, whilst the two channels downstream of the bifurcation point required 1 x sliding bulkhead and 1 x roller bulkhead each.

The isolation bulkheads were custom-designed to retrofit the existing civil structure, accommodate uni-directional sealing and allow insertion under low flow differential water pressure. They were also reversible to facilitate wet commissioning activities.

Whilst Fulton Hogan was responsible for the installation process, they utilised one of AWMA’s certified installers to mitigate project risk.

The wet commissioning process delivered a leak-free isolation, ensuring the channels can be successfully and safely remediated.