Watercare’s new water treatment plant by the Waikato River will provide up to 50 million litres of water a day, marking a critical milestone in the organisation’s drought response and catering for growth in the Auckland region.

The ‘Waikato 50’ plant was designed and built in under a year. The new plant sits alongside Watercare’s existing plant near Tuakau.

The Waikato A Phase 1 project was developed to provide the first stage of the new Water Treatment Plant, with a floating pump station and pipeline from the Waikato River.

The plant will obtain water from the more resilient and larger catchment river feed, allowing the water storage dams in the Hūnua and Waitakere ranges, time to recover.

AWMA were involved in the Early Contractor Involvement (ECI) process as a key supplier with multiple contributors. As the project developed AWMA was engaged directly through Watercare Services Ltd to design and manufacture intake screens for the new pump station.

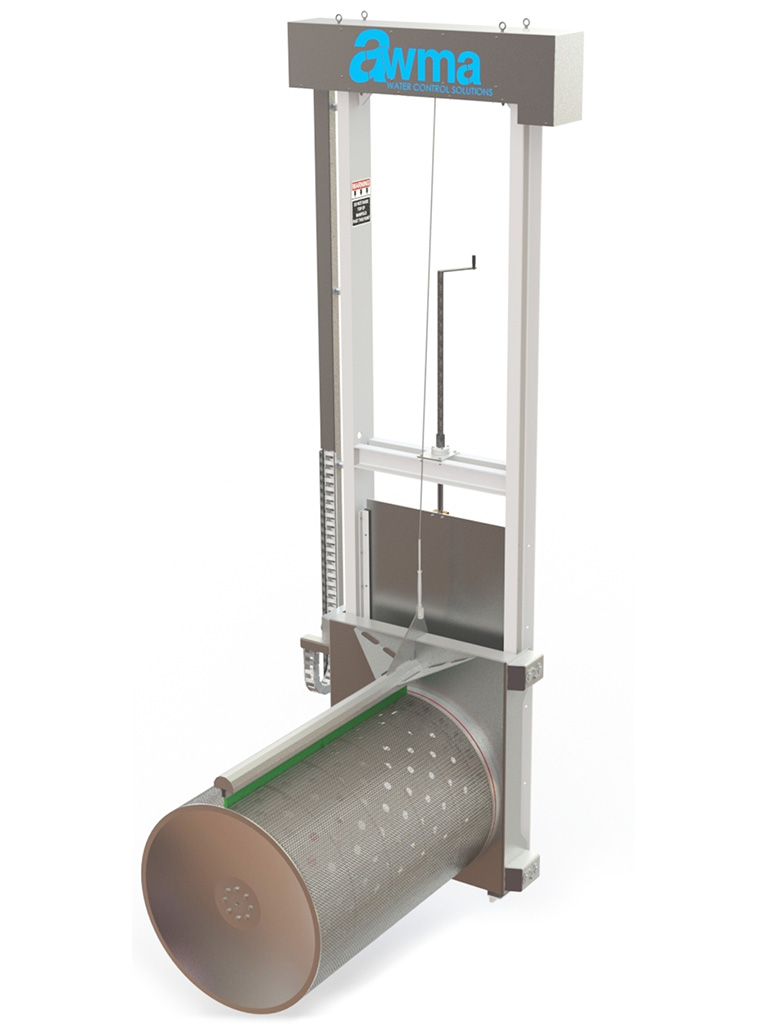

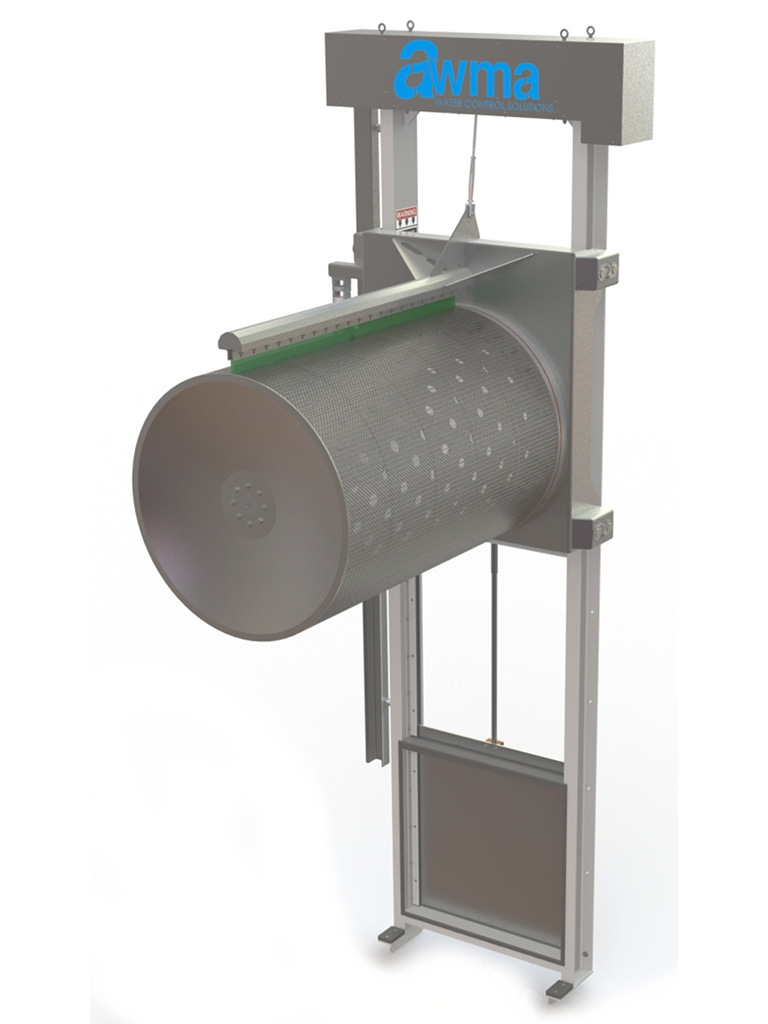

Two AWMA Cylinder Screens were supplied for the raw water intakes, compliant with the fish and debris exclusion screen regulatory requirements. They were 1400mm diameter x 2000mm long with internal and external cleaning brushes for automated self-cleaning capability. Custom designed retrieval systems were also supplied for each screen, allowing safe and efficient inspection and/or maintenance should it be required, without the need for divers.

The Intake Screen Design Process was focused on delivering the required flow rate and meeting the specified fish exclusion criteria, resulting in:

- utilising a 1.5mm wedge wire aperture,

- minimizing velocities with a 0.15m/s through screen (slot) velocity rate

- materials to include grade 304 stainless steel for 50year design life

- maintaining a clean screen surface to accommodate the river weed and debris conditions that were expected.

AWMA’s self-cleaning screen system utilising internal and external brushes, was well received by the project partners who declared them the best available technology for this application.

The existing water treatment plant's intake screens require regular, underwater maintenance, to clean the screens from algae build-up which can be an inconvenient, safety challenging and costly process.

The Waikato River Water Treatment Plant now provides up to 50 percent of the drinking water for the Auckland region.

Brush-cleaned cylinder screens are designed and manufactured by AWMA under a licensing agreement with Intake Screens, Inc.

"The intake screens installed for the Waikato50 site have been performing extremely well over the last 10 months with minimal operations and maintenance input required. They are compliant with the fish and debris exclusion screen regulatory requirements and the self-cleaning function significantly reduces safety critical work and operator attendance on a floating pump station in the river."

Sven Harlos Programme Manager Waikato R2R at Watercare Services Ltd New Zealand